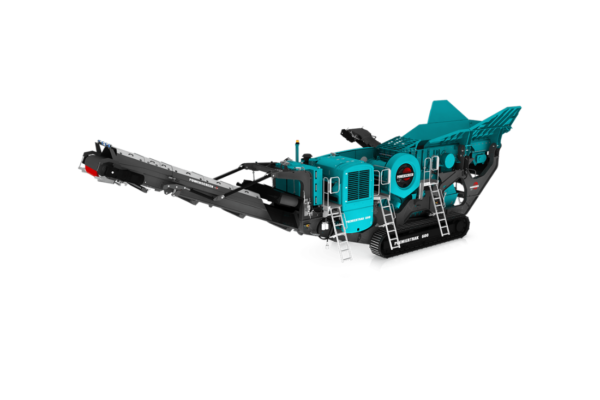

2024 Powerscreen Premiertrak 600 Long Feeder Jaw Crusher

The Premiertrak 600 Long Feeder is specifically designed to handle the toughest quarry applications, particularly where larger excavators are in use. It boasts a significantly larger hopper and an extended pan feeder, allowing it to manage higher volumes of material efficiently. This rugged machine is built to last and can be fed by bigger excavators than the standard Premiertrak 600, making it ideal for demanding and heavy-duty environments.

Highlights

- Built for High-Volume Tasks

- Increased Feed Capacity

- Improved Material Loading Efficiency

Reference No.

AMH085

2024 Powerscreen Premiertrak 600 Long Feeder Jaw Crusher: Robust Performance for Heavy-Duty Quarry Operations

The 2024 Powerscreen Premiertrak 600 Long Feeder Jaw Crusher is engineered to tackle the most demanding quarry applications, particularly in scenarios involving larger excavators. This advanced machine combines powerful crushing performance with enhanced feeding capabilities, making it a top choice for handling high volumes of material efficiently and reliably.

High-Capacity Feeding for Optimal Performance

The Premiertrak 600 Long Feeder is designed with an extended pan feeder and a significantly larger hopper, enabling it to manage larger volumes of material compared to standard models. This upgraded design allows for seamless feeding by bigger excavators, which enhances throughput and reduces the need for frequent reloading. By accommodating larger material sizes and volumes, this jaw crusher ensures that operations run smoothly and efficiently, even under the most challenging conditions.

Engineered for Durability and Reliability

Built to withstand the rigors of heavy-duty quarry work, the Premiertrak 600 Long Feeder features a robust construction that ensures long-lasting performance and minimal maintenance. Its heavy-duty components and rugged design are specifically crafted to handle high-impact loads and harsh environments, providing reliable operation and reducing downtime. This durability translates to a longer service life and lower operational costs, making it a valuable investment for any quarrying operation.

Advanced Technology for Enhanced Efficiency

The Premiertrak 600 Long Feeder is equipped with the latest technological advancements to optimize its performance and operational efficiency. The machine features an advanced control system that allows for precise adjustments and real-time monitoring, ensuring that the crusher operates at peak efficiency. The integration of sophisticated automation technology also simplifies operation and enhances safety, providing operators with intuitive controls and valuable insights into the machine’s performance.

Improved Material Handling

With its enhanced feed capacity and advanced material handling features, the Premiertrak 600 Long Feeder ensures efficient and consistent material loading. The extended pan feeder is designed to improve material flow and reduce blockages, allowing for a continuous and uninterrupted operation. This efficient material handling system contributes to higher productivity and reduced wear on the crusher, making it ideal for high-volume applications.

Versatile Applications

The Premiertrak 600 Long Feeder is versatile enough to handle a wide range of materials, including large, tough rock and aggregate types. Its ability to process various material sizes and types makes it suitable for diverse applications within the quarrying and mining industries. Whether used for primary crushing or as part of a larger processing line, this jaw crusher delivers exceptional performance and adaptability.

Conclusion

The 2024 Powerscreen Premiertrak 600 Long Feeder Jaw Crusher is a powerful and reliable solution for demanding quarry operations. With its enhanced feeding capabilities, durable construction, and advanced technology, it is designed to handle high volumes of material efficiently and effectively. Its robust performance and versatility make it a valuable addition to any heavy-duty crushing operation, ensuring exceptional productivity and long-term reliability.

| Working Hours | 0 |

|---|---|

| Operating Weight | 76,650 KG |

| Engine Make | SCANIA |

| Engine Model | DC13 |

| Crushing Output Dimensions | Max: 200mm, Min: 75mm |

| Hopper | 9.3 m3 |

| EPA | Certified |

| Emissions | EU Stage IV, Tier 4 Final |

| Features | Long feeder for extra heavy quarry applications |

Online

Accept all credit/debit cards

Bank Transfer

Manual money transfer

In-person

Physically present at the office

Digital Wallet

Using cryptocurrency to pay

Shipping & Delivery

Local round trip and world wide drop off to your nearest port.

Self Pick Up

Pick up from our showroom; Free of cost.