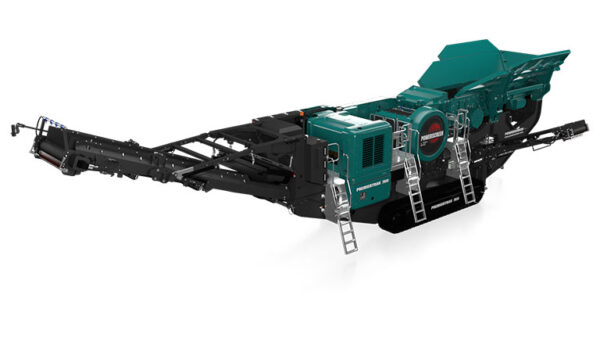

2024 Powerscreen Premiertrak 760 Jaw Crusher

The 2024 Powerscreen Premiertrak 760 Jaw Crusher is a powerful and efficient solution for your crushing needs, combining high-capacity performance with cutting-edge automation. Engineered for durability and fuel efficiency, this versatile crusher excels in a range of applications. It boasts quick and straightforward setup, long-lasting jaw plates, and enhanced mobility for smooth material handling and easy operation. Ideal for challenging projects, the Premiertrak 760 is built to deliver exceptional performance and reliability.

Highlights:

- High-Capacity Crushing Performance

- Innovative Automation Features

- Robust Construction

Reference No.

AMH090

2024 Powerscreen Premiertrak 760 Jaw Crusher: Unmatched Power and Efficiency for Crushing

The 2024 Powerscreen Premiertrak 760 Jaw Crusher is designed to deliver high-capacity crushing power with advanced automation technology, making it an essential asset for various applications in the construction and mining industries. This state-of-the-art crusher combines robust construction with superior fuel efficiency, providing outstanding performance and reliability in even the most demanding environments.

Exceptional Crushing Power

The Premiertrak 760 is engineered for exceptional crushing performance, featuring a powerful jaw crusher that handles the toughest materials with ease. Its high-capacity design ensures that large volumes of material are processed efficiently, maximizing productivity and minimizing downtime. With its advanced hydraulic system and precision-engineered components, the Premiertrak 760 delivers consistent, high-quality results, making it an ideal choice for heavy-duty applications.

Advanced Automation Technology

The 2024 Premiertrak 760 incorporates cutting-edge automation technology that enhances its operational efficiency and ease of use. The advanced control system allows for precise adjustments and monitoring, ensuring optimal performance and safety. Operators can easily manage the crusher’s settings and functions from a user-friendly interface, streamlining the workflow and improving overall productivity. The automation features also include real-time diagnostics and remote monitoring capabilities, providing valuable insights into the machine’s performance and helping to prevent potential issues before they arise.

Durable Construction and Fuel Efficiency

Built with heavy-duty materials and engineered for durability, the Premiertrak 760 is designed to withstand the rigors of demanding job sites. Its robust construction ensures long-term reliability and minimal maintenance requirements, reducing operational costs and extending the machine’s service life. Additionally, the crusher’s superior fuel efficiency helps to lower operating expenses, making it a cost-effective solution for high-volume crushing tasks.

Quick and Easy Setup

The Premiertrak 760 is designed for quick and hassle-free setup, allowing operators to get up and running in no time. Its modular design and straightforward assembly process simplify the installation, while the integrated mobility features enable easy relocation between job sites. This flexibility ensures that the Premiertrak 760 can adapt to various operational requirements and environments, providing versatility and convenience for a wide range of projects.

Enhanced Mobility and Material Flow

With its advanced mobility features, the Premiertrak 760 offers enhanced maneuverability on the job site. The crusher’s efficient material handling system ensures smooth and continuous flow, reducing blockages and improving overall operational efficiency. The durable jaw plates are designed to withstand heavy wear, providing reliable performance and consistent results throughout the machine’s lifespan.

Conclusion

The 2024 Powerscreen Premiertrak 760 Jaw Crusher sets a new standard for high-capacity crushing with its blend of power, automation, and durability. Whether you’re working in construction, mining, or any other heavy-duty application, this crusher delivers exceptional performance and reliability. Its advanced technology, robust construction, and user-friendly features make it a valuable addition to any operation, offering unmatched efficiency and productivity for even the most challenging tasks.

| Working Hours | 0 |

|---|---|

| Operating Weight | 83,450 KG |

| Engine Make | Cat |

| Engine Model | C13 |

| Engine Power | 385 Hp |

| Fuel Capacity | 1000 liters |

| Crusher | 750 tph (827 US tph) |

| Crushing Output Dimensions | Max CSS: 225mm, Min CSS: 75 mm |

| Hopper | 10 m3 |

| EPA | Certified |

| Emissions | EU Stage IIIA, Tier 3 |

| Features | Output potential of up to 750tph, depending on material type |

Online

Accept all credit/debit cards

Bank Transfer

Manual money transfer

In-person

Physically present at the office

Digital Wallet

Using cryptocurrency to pay

Shipping & Delivery

Local round trip and world wide drop off to your nearest port.

Self Pick Up

Pick up from our showroom; Free of cost.