2024 Powerscreen Warrior 2400 Scalping Screener

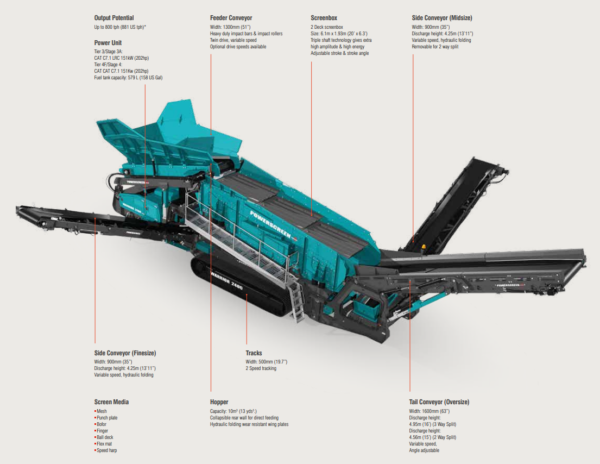

The Powerscreen Warrior 2400 is a powerful scalping screener built for heavy-duty tasks in large-scale quarrying and mining. It's designed to effortlessly handle bigger feed sizes and deliver high throughput. Equipped with a robust incline screen and a high-amplitude triple shaft drive, it's perfect for efficiently screening, scalping, splitting, and stockpiling materials like aggregates, topsoil, coal, demolition waste, and iron ore. The Warrior 2400 also features a convenient slide-out tail conveyor for easy maintenance and a load-sensing conveyor that helps prevent blockages, ensuring dependable and efficient material processing in quarrying, mining, and recycling environments.

Highlights:

- High-Amplitude Triple Shaft Drive

- Quick Setup and Mobility

- Precise Material Separation

Reference No.

AMH185

2024 Powerscreen Warrior 2400 Scalping Screener: Unmatched Performance for Demanding Applications

The 2024 Powerscreen Warrior 2400 Scalping Screener is the latest evolution in Powerscreen’s line of heavy-duty screening solutions, engineered to meet the rigorous demands of large-scale quarrying, mining, and recycling operations. Known for its robustness, efficiency, and versatility, the Warrior 2400 continues to set industry standards with cutting-edge technology, delivering exceptional performance across a wide range of applications.

Optimized for Large-Scale Operations

The Warrior 2400 is designed for the toughest jobs, handling larger feed sizes and higher throughputs with ease. Whether you’re working with aggregates, topsoil, coal, demolition waste, or iron ore, this machine is built to process vast quantities of material quickly and efficiently. Its impressive capacity ensures that even the most demanding projects can be completed on time and within budget, reducing downtime and maximizing productivity.

Advanced Screening Technology

At the heart of the Warrior 2400 is its high-amplitude triple shaft drive system, a feature that sets it apart from other screeners on the market. This powerful drive delivers aggressive screening action, ensuring precise material separation and reducing the risk of blockages. The incline screen is built to withstand heavy-duty use, making it ideal for scalping and separating materials in the harshest conditions. The result is a machine that consistently delivers high-quality output, meeting the exacting standards required by modern industries.

Versatility and Flexibility

One of the standout features of the 2024 Warrior 2400 is its versatility. This screener is not only capable of handling a wide range of materials but can also be easily configured to meet the specific needs of your operation. Whether you need to screen, scalp, split, or stockpile, the Warrior 2400 adapts to the task at hand. Its quick setup time and mobility make it an excellent choice for operations that require frequent relocation or rapid deployment. The machine’s adjustable settings allow for precise control over the screening process, ensuring optimal performance in every application.

User-Friendly Design

The Warrior 2400 has been designed with the operator in mind, featuring a range of innovations that enhance usability and reduce maintenance. One of the key enhancements is the slide-out tail conveyor, which provides easy access for maintenance and cleaning. This design not only saves time but also improves safety by minimizing the need for operators to access hard-to-reach areas. Additionally, the load-sensing conveyor system automatically adjusts to prevent blockages, further reducing downtime and increasing the overall efficiency of the machine.

Built for Reliability and Durability

Reliability is at the core of the Warrior 2400’s design. Constructed with high-quality components and engineered for durability, this machine is built to withstand the toughest working environments. The heavy-duty construction ensures that the Warrior 2400 can endure the daily wear and tear of intense operations, while its advanced engineering minimizes the need for frequent repairs. This combination of strength and reliability makes the Warrior 2400 a cost-effective solution, offering a long service life and a high return on investment.

Enhanced Operational Efficiency

In addition to its robust design and powerful performance, the Warrior 2400 is also engineered to optimize operational efficiency. The machine’s advanced hydraulic system is designed to minimize fuel consumption while maximizing output, reducing operating costs and environmental impact. Its intelligent control system allows operators to monitor and adjust settings with ease, ensuring that the machine operates at peak efficiency at all times.

Conclusion

The 2024 Powerscreen Warrior 2400 Scalping Screener is the ultimate solution for large-scale material processing. With its unmatched combination of power, versatility, and user-friendly features, it is designed to meet the challenges of modern quarrying, mining, and recycling operations. Whether you’re looking to increase productivity, reduce costs, or improve the quality of your output, the Warrior 2400 delivers the performance you need to stay ahead in today’s competitive market.

| Working Hours | 0 |

|---|---|

| Operating Weight | 44,600 KG |

| Engine Make | Cat |

| Engine Model | C7.1 |

| Engine Power | 202 Hp |

| Fuel Capacity | 579 liters |

| Hopper | 10 m3 |

| Emissions | EU Stage IV, Tier 4 Final |

| Features | Up to 800 tph (881 US tph) output potential |

Online

Accept all credit/debit cards

Bank Transfer

Manual money transfer

In-person

Physically present at the office

Digital Wallet

Using cryptocurrency to pay

Shipping & Delivery

Local round trip and world wide drop off to your nearest port.

Self Pick Up

Pick up from our showroom; Free of cost.